Product Detail

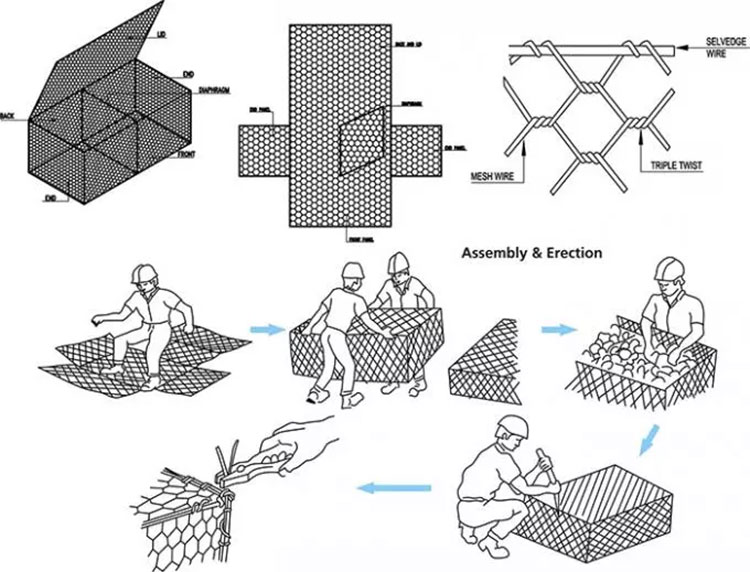

The Gabion basket is also called the stone cage boxes, the Reno mattress, which means the thickness of the mesh made up by the machine is much smaller than the length and width of the Gabion basket .It is used as the anti-scour structure of water embankment, bank slope and so on. It has the advantages of flexibility and adaptability to the foundation. They are made of heavy galvanized wire / ZnAl (Golfan) coated wire / PVC coated wires, the mesh shape is hexagonal style.

| Gabion bakset common specification | |||

| Gabion box (mesh size): 80*100mm 100*120mm | Mesh wire Dia. | 2.7mm | zinc coating:60g,245g, ≥270g/m2 |

| Edge wire Dia. | 3.4mm | zinc coating:60g,245g, ≥270g/m2 | |

| Tie wire Dia. | 2.2mm | zinc coating:60g,≥220g/m2 | |

| Gabion mattress(mesh size): 60*80mm | Mesh wire Dia. | 2.2mm | zinc coating:60g, ≥220g/m2 |

| Edge wire Dia. | 2.7mm | zinc coating:60g,245g, ≥270g/m2 | |

| Tie wire Dia. | 2.2mm | zinc coating:60g, ≥220g/m2 | |

| special sizes Gabion are available

| Mesh wire Dia. | 2.0~4.0mm | superior quality,competitive price and considerate service |

| Edge wire Dia. | 2.7~4.0mm | ||

| Tie wire Dia. | 2.0~2.2mm | ||

Applications

1. Control and guide the rivers and floods

2. Spillway dam and diversion dam

3. Rock fall protection

4. To prevent water loss

5. Bridge protection

6. Solid soil structure

7. Coastal defense works

8. Port project

9. Retaining Walls

10. Road Protection

Features

(1) It is convenient to use, and can be used only by tiling the net surface into wall surfaces and building cement;

(2) the construction is simple and does not need special technology;

(3) Strong ability to resist natural damage, corrosion and adverse weather effects;

(4) can withstand large-scale deformation without collapsing. It plays a role in fixing heat preservation and heat insulation.

(5) The excellent technological foundation ensures the uniformity of coating thickness and has stronger corrosion resistance;

(6) Save transportation costs. It can be shrunk into small rolls and wrapped in moisture-proof paper, occupying little space.

2. Weaving Process quality control For each gabion, we have strict QC system to inspect the mesh hole, mesh size and gabion size.1. Raw Material Inspection Inspecting wire diameter, tensile strength, hardness and zinc coating and PVC coating, etcThe gabion box package is folded and in bundles or in rolls. We also can pack it according to customers special request3. Weaving Process quality control The most advanced machine 19 sets to make every gabion mesh Zero Defect.4. Packing Every gabion box is compact and weighted then packed into pallet for shipment,

2. Weaving Process quality control For each gabion, we have strict QC system to inspect the mesh hole, mesh size and gabion size.1. Raw Material Inspection Inspecting wire diameter, tensile strength, hardness and zinc coating and PVC coating, etcThe gabion box package is folded and in bundles or in rolls. We also can pack it according to customers special request3. Weaving Process quality control The most advanced machine 19 sets to make every gabion mesh Zero Defect.4. Packing Every gabion box is compact and weighted then packed into pallet for shipment,