Product Detail

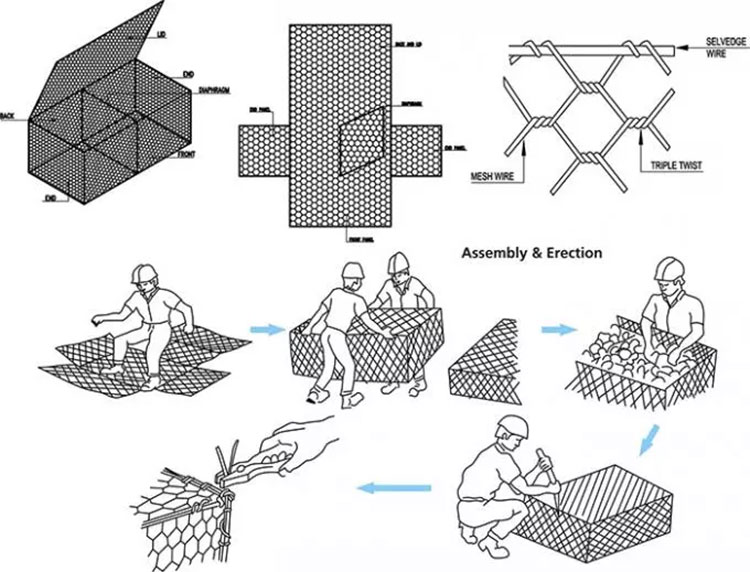

Stone filled baskets are called Gabions, Gabion baskets etc. The usage of Welded gabion baskets are being accepted world wide for soil prevention at river banks, ponds, lakes, sea coasts, bridges etc. Also it is being utilised for landscaping in residential town ships, universities, schools, public gardens, schools etc in today's life.

Material:

(1) Galvanized steel wire: diameter 2.0MM-4.0MM, tensile strength >380Mpa, zinc :240g / m2.

(2) Zinc 5% Aluminum - wire diameter 1.0MM-3.0MM, tensile strength >380Mpa.

(3) Coated galvanized steel wire: low carbon steel wire PVC coated.

| Gabion bakset common specification | |||

| gabion baskets (mesh size): 80*100mm 100*120mm | Mesh wire Dia. | 2.7mm | zinc coating:60g,245g, ≥270g/m2 |

| Edge wire Dia. | 3.4mm | zinc coating:60g,245g, ≥270g/m2 | |

| Tie wire Dia. | 2.2mm | zinc coating:60g,≥220g/m2 | |

| Gabion mattress(mesh size): 60*80mm | Mesh wire Dia. | 2.2mm | zinc coating:60g, ≥220g/m2 |

| Edge wire Dia. | 2.7mm | zinc coating:60g,245g, ≥270g/m2 | |

| Tie wire Dia. | 2.2mm | zinc coating:60g, ≥220g/m2 | |

| special sizes Gabion are available

| Mesh wire Dia. | 2.0~4.0mm | superior quality,competitive price and considerate service |

| Edge wire Dia. | 2.7~4.0mm | ||

| Tie wire Dia. | 2.0~2.2mm | ||

Application

• Control and guide of water or flood

• Flood bank or guiding bank

• Prevention of rock breaking

• Water and soil protection

• Bridge protection

• Strengthening structure of soil

• Protection engineering of seaside area

• Seaport engineering

• Isolation walls

• Protection of road

Company Profile

Anping Haochang Wire Mesh Manufacture Co.,Ltd is the biggest gabion wire mesh factory in Anping. It was established in 2006.Our factory covers an area of 39000 square meters.Our company established integrated and scientific system of the quality control.We passed through the ISO:9001-2000 quality controlling.

Our service

To the quality and credibility of the motto for development, to provide customers with reasonable prices, prompt delivery, excellent customer service. We sincerely hope that with the new and old friends to establish a good long-term business relationship, mutual benefit.

2. Weaving Process quality control For each gabion, we have strict QC system to inspect the mesh hole, mesh size and gabion size.1. Raw Material Inspection Inspecting wire diameter, tensile strength, hardness and zinc coating and PVC coating, etcThe gabion box package is folded and in bundles or in rolls. We also can pack it according to customers special request3. Weaving Process quality control The most advanced machine 19 sets to make every gabion mesh Zero Defect.4. Packing Every gabion box is compact and weighted then packed into pallet for shipment,

2. Weaving Process quality control For each gabion, we have strict QC system to inspect the mesh hole, mesh size and gabion size.1. Raw Material Inspection Inspecting wire diameter, tensile strength, hardness and zinc coating and PVC coating, etcThe gabion box package is folded and in bundles or in rolls. We also can pack it according to customers special request3. Weaving Process quality control The most advanced machine 19 sets to make every gabion mesh Zero Defect.4. Packing Every gabion box is compact and weighted then packed into pallet for shipment,