Product Detail

Gabion baskets are made of heavy galvanized wire / ZnAl (Galfan) coated wire / PVC or PE coated wires the mesh shape is hexagonal style. The gabion baskets are used widely in slope protection foundation pit supporting mountain rock holding river and dams scour protection.

It is mainly used as the slope protection structure of river, bank slope and subgrade slope.It can prevent the river from being destroyed by water flow and wind waves, and realize the natural convection and exchange function between the water body and the soil under the slope to achieve the ecological balance.Slope planting green can add landscape and greening effect.

| Gabion bakset common specification | |||

| Gabion box (mesh size): 80*100mm 100*120mm | Mesh wire Dia. | 2.7mm | zinc coating:60g,245g, ≥270g/m2 |

| Edge wire Dia. | 3.4mm | zinc coating:60g,245g, ≥270g/m2 | |

| Tie wire Dia. | 2.2mm | zinc coating:60g,≥220g/m2 | |

| Gabion mattress(mesh size): 60*80mm | Mesh wire Dia. | 2.2mm | zinc coating:60g, ≥220g/m2 |

| Edge wire Dia. | 2.7mm | zinc coating:60g,245g, ≥270g/m2 | |

| Tie wire Dia. | 2.2mm | zinc coating:60g, ≥220g/m2 | |

| special sizes Gabion are available

| Mesh wire Dia. | 2.0~4.0mm | superior quality,competitive price and considerate service |

| Edge wire Dia. | 2.7~4.0mm | ||

| Tie wire Dia. | 2.0~2.2mm | ||

Features

1.Economic and environmental protection

2.The construction is simple, no special technology is needed, just fill the stone into the gabion and seal it

3.It has a strong ability to resist natural damage, corrosion resistance and adverse weather effects.

4.Can withstand large-scale deformation without collapsing.

5.The silt between the stones in the cage is conducive to plant production and can be integrated with the surrounding natural environment.

6.It has good permeability and can prevent damage caused by hydrostatic force.

7.Save transportation costs. It can be folded up for transportation and assembled on site.

Packing: The gabion box package is folded and in bundles or in rolls. We also can pack it according to customers special request

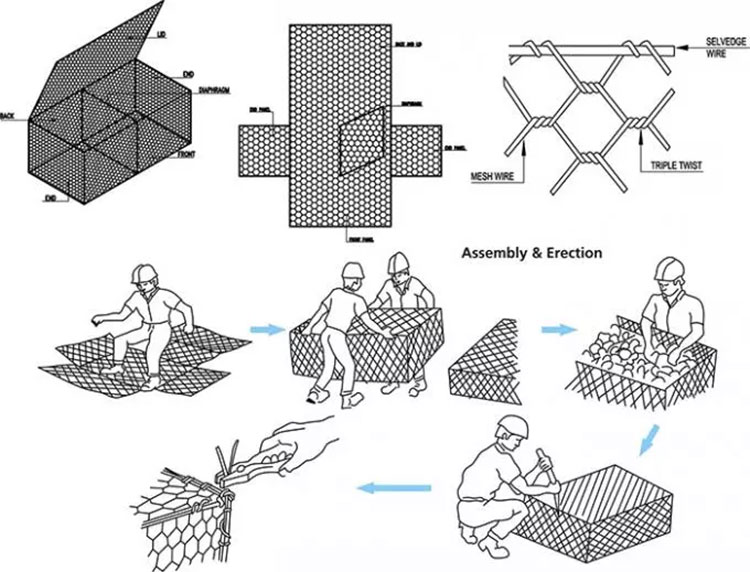

1. Ends,diaphragms,front and back panels are placed upright on the bottom section of wire mesh 2. Secure panels by screwing sprial binders through the mesh openings in adjacent panels 3. Stiffeners shall be placed across the corners, at 300mm from the corner. Providing a diagonal bracing,and crimped 4. Box gabion filled with graded stone by hand or with a shovel. 5. After filling,close the lid and secure with sprial binders at the diaphragms,ends,front and back. 6. When stacking tiers of the weled gabion,the lid of the lower tier may serve as base of the upper tier.Secure with sprial binders and add pre-formed stiffeners to exterior cells before filling with graded stones.

2. Weaving Process quality control For each gabion, we have strict QC system to inspect the mesh hole, mesh size and gabion size.1. Raw Material Inspection Inspecting wire diameter, tensile strength, hardness and zinc coating and PVC coating, etcThe gabion box package is folded and in bundles or in rolls. We also can pack it according to customers special request3. Weaving Process quality control The most advanced machine 19 sets to make every gabion mesh Zero Defect.4. Packing Every gabion box is compact and weighted then packed into pallet for shipment,

2. Weaving Process quality control For each gabion, we have strict QC system to inspect the mesh hole, mesh size and gabion size.1. Raw Material Inspection Inspecting wire diameter, tensile strength, hardness and zinc coating and PVC coating, etcThe gabion box package is folded and in bundles or in rolls. We also can pack it according to customers special request3. Weaving Process quality control The most advanced machine 19 sets to make every gabion mesh Zero Defect.4. Packing Every gabion box is compact and weighted then packed into pallet for shipment,